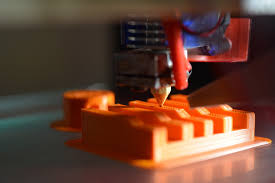

Tired of failed prints? You’re not alone. Many hobbyists and professionals alike throw away hundreds of dollars on bad materials, all while wondering what went wrong. This guide is packed with expert advice to help you choose the right 3D printer filament for your projects. Stop wasting money and start getting perfect prints.

Why Your Choice of 3D Printer Filament Quality Matters

Think of your 3D printer like a high-performance sports car. You wouldn’t fill a Ferrari with cheap fuel and expect it to deliver peak performance, right? The same principle applies to 3D printing. The filament you use directly affects the outcome of your prints—from strength and durability to surface finish and accuracy.

In fact, the secret to achieving professional, flawless results isn’t necessarily investing in the latest 3D printer model. Instead, it’s about choosing the right 3D printer filament from the very beginning. High-quality materials ensure smoother extrusion, better adhesion, and fewer failed prints, ultimately saving you both time and money.

The Hidden Costs of Using Low-Quality 3D Printer Filament

A cheap spool of 3D printer filament may look like a bargain at first glance, but the real costs go far beyond the price tag. Low-quality filament often introduces hidden problems that waste your time, damage your printer, and drain the enjoyment out of 3D printing.

1. Wasted Time

Failed prints don’t just waste plastic—they waste hours, sometimes even days. You’ll find yourself re-slicing, re-calibrating, and re-printing over and over again.

2. Frustration and Burnout

What should be a fun, creative hobby can quickly become a frustrating chore. The endless cycle of print failures and troubleshooting can sap your motivation and turn 3D printing into a stressful experience.

3. Risk of Printer Damage

Cheap filament often comes with inconsistent diameters or impurities. This can cause your extruder gears to grind, leading to stripped material and poor extrusion. Even worse, it increases the chances of nozzle clogs—a messy, time-consuming problem that may require replacing parts altogether.

Trust me, investing in quality filament pays off. You’ll save yourself endless headaches, keep the fun in 3D printing, and enjoy amazing results with every project.

7 Pro Tips for Choosing the Perfect 3D Printer Filament

Enough talk—let’s dive straight into the good stuff. Here are seven pro tips that will help you pick the perfect filament and level up your 3D printing.

Tip #1: Understand Your Project Needs

The world of 3D printer filament is huge, and choosing the right type starts with knowing your goals. Each material comes with its own strengths, weaknesses, and ideal use cases.

PLA (Polylactic Acid): The Beginner’s Best Friend

-

Pros: Easy to print, minimal warping, no strong odor, and eco-friendly since it’s made from renewable sources like cornstarch. Perfect for prototypes, display models, and decorative prints.

-

Cons: Limited durability, prone to brittleness, and low heat resistance.

ABS (Acrylonitrile Butadiene Styrene): The Durable Workhorse

-

Pros: Strong, impact-resistant, and able to withstand higher temperatures. Great for mechanical parts, functional prototypes, and stress-tested components.

-

Cons: Requires a heated bed and often an enclosed printer to reduce warping. Emits noticeable plastic fumes while printing.

PETG (Polyethylene Terephthalate Glycol): The Best of Both Worlds

-

Pros: Combines the strength of ABS with the easy printability of PLA. Strong, flexible, excellent layer adhesion, and food-safe in its pure form.

-

Cons: Can produce stringing issues, requiring careful retraction settings.

Once you’re comfortable with the fundamentals above stated, you can experiment with specialty filaments such as:

-

TPU (Thermoplastic Polyurethane): Flexible and rubber-like, ideal for phone cases and wearables.

-

Wood-Infused Filament: Creates a realistic wood finish for artistic or decorative pieces.

-

Carbon Fiber or Metal-Filled Filament: Adds strength, texture, or a premium look to your prints.

For additional guidance, we’ve put together a detailed resource Mastering Smooth PLA Prints: The Comprehensive Guide to Perfect 3D Printing Results

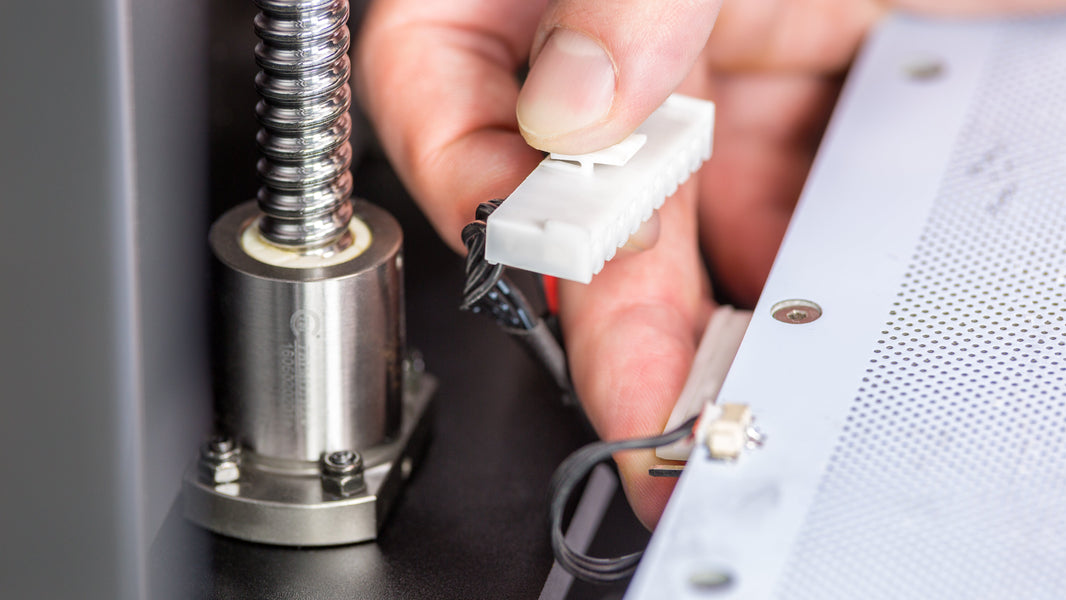

Tip #2: Check the Diameter and Tolerance — Precision is Everything

When it comes to 3D printer filament, consistency is key. One of the most overlooked yet critical factors is the filament’s diameter and tolerance. A high-quality spool maintains the same diameter throughout its entire length, ensuring predictable and smooth extrusion.

Here’s why it matters: your 3D printer’s extruder is calibrated to feed a specific amount of plastic. If the diameter drops from 1.75 mm to 1.70 mm, the printer still pushes the same volume, which leads to under-extrusion and weaker layers. On the flip side, if the filament suddenly thickens, you risk jams, clogs, or even damage to your nozzle.

To avoid these issues, always choose a manufacturer that guarantees a tight tolerance—±0.03 mm or better. This level of precision shows they take quality control seriously, giving you consistent performance, fewer headaches, and more reliable prints.

Tip #3: Store Filament Properly and Protect It from Moisture

Here’s something many beginners don’t realize: moisture is the silent killer of 3D printer filament. Materials like PLA, PETG, and Nylon are hygroscopic, meaning they absorb water from the air. Even a small amount of moisture can ruin your prints.

Common Signs of Moisture-Damaged Filament:

-

Bubbling and Sizzling: Trapped water vaporizes inside the hotend, creating popping sounds and surface bubbles.

-

Weak Layer Adhesion: Moisture weakens the polymer structure, making layers bond poorly and prints more fragile.

-

Stringing and Blobs: Wet filament flows inconsistently, leaving messy strings and surface imperfections.

The Fix: Proper Storage

The good news? Preventing moisture damage is simple. Always keep your spools in an airtight container with desiccant packs when not in use. For the best results, consider using a dedicated solution like the UFM PrintStation Storage, designed specifically to protect your filament from humidity while keeping it organized and ready to print.

By storing your filament correctly, you’ll extend its lifespan, improve print reliability, and avoid wasting both time and material.

Tip #4: Don’t Overlook Brand Reputation and Reviews

A cheap spool of 3D printer filament might seem like a bargain, but price alone doesn’t tell the whole story. Reputable brands invest in research, quality control, and consistency—and that translates to fewer failures, smoother printing, and better long-term value.

Do Your Research Before Buying

Before committing to a new filament brand, take a little time to investigate:

-

Check Online Reviews: Browse reviews on e-commerce platforms, but don’t stop there. Explore specialized forums and 3D printing communities for real user feedback on print quality, consistency, and customer service.

-

Learn from Real-World Testing: Instead of relying on marketing claims, seek out practical demonstrations and results. At UFM Design, we regularly test filaments in real printing scenarios and share insights with our community so you know what works best.

Start Small: When trying a new brand, order a single spool before buying in bulk. This way, you minimize risk while evaluating the filament’s quality.

Tip #5: Match the Filament to Your Printer’s Capabilities

Not all 3D printer filaments are created equal—and not every printer can handle every material. Using the wrong combination can lead to poor results or even damage your equipment.

Example: Carbon Fiber Filaments

Carbon fiber–reinforced filaments are incredibly strong but also highly abrasive. If you use them with a standard brass nozzle, it will wear out quickly. To print them successfully, you’ll need a hardened steel nozzle or a ruby-tipped nozzle that’s built to withstand the extra wear.

Example: ABS and Nylon

Both ABS and Nylon require higher temperatures and more controlled environments. To prevent warping and ensure strong layer adhesion, you’ll need:

-

A heated print bed

-

Preferably an enclosed build chamber

Without these features, prints with these filaments are much more likely to fail.

Know Your Printer’s Limits

Before experimenting with new materials, always check your printer’s manual or the manufacturer’s website for supported filament types and hardware requirements. Matching your filament to your printer’s capabilities ensures smoother printing, longer hardware lifespan, and consistent results.

Tip #6: Consider Specific Applications (Food Safety and Professional Use)

For professionals—especially in dentistry, healthcare, or food service—choosing the right filament is about more than print quality. It’s also about safety. One of the most common questions is: “Is food-safe 3D printer filament actually safe?”

Food-Contact Safe vs. Food-Safe Printing

-

Food-Contact Safe Filaments: Materials like pure PLA and PETG are generally considered non-toxic and won’t leach harmful chemicals, making them suitable for temporary food-contact applications.

-

Food-Safe Printing: This is more complex. The microscopic grooves and layer lines of 3D prints can trap bacteria, making thorough sanitization nearly impossible. In addition, contaminants from the printer itself—such as residue from the nozzle—can compromise safety.

Practical Considerations for Professionals

-

Dentists: For non-permanent dental models, food-contact safe filaments may be adequate. However, for items that will be used inside a patient’s mouth, strict sterilization protocols and certified biocompatible materials are essential.

-

Food Service Applications: Any tool or part that touches food regularly should either be printed with officially certified food-safe materials or finished with a food-safe coating to minimize contamination risk.

Tip #7: Buy Local – The Hidden Advantage of “3D Printer Filament Near Me”

In today’s globalized world, it’s easy to default to overseas suppliers. But don’t underestimate the benefits of buying 3D printer filament locally. A quick search for “3D printer filament near me” can save you both time and money, while also strengthening your local 3D printing community.

Why Buying Local Matters:

-

Faster Delivery: Skip the long waits. Local suppliers often deliver within days—or even the same day—so you can get printing right away.

-

Lower Shipping Costs: Many local sellers offer free or reduced shipping once you hit a minimum order value.

-

Responsive Customer Service: If something goes wrong, replacements and support are typically quicker and more reliable with local businesses.

- Community Support: Every purchase from a local supplier helps grow the 3D printing ecosystem in your area, encouraging more innovation and availability of materials.

💡 Pro Tip: Whether you’re in the US, Europe, or beyond—choosing a trusted supplier in your own region saves you time, money, and headaches while ensuring consistent filament quality. That’s why many makers turn to UFM Design, which offers premium filaments with fast, reliable international shipping tailored for Western markets.

Frequently Asked Questions About 3D Printer Filament

You’ve got questions, we’ve got answers. Here are some of the most common things makers ask when it comes to 3D printer filament.

Q: How do I dry out wet 3D printer filament?

A: The easiest way is to use a dedicated filament dryer box. If you don’t have one, a food dehydrator or even a conventional oven set to a very low temperature (around 40–50°C for PLA) can do the job. Just be careful—too much heat will melt the plastic instead of saving it.

Q: What’s the best way to store leftover filament spools?

A: Always keep your filament away from moisture. The best method is to store spools in an airtight container or large Ziploc bag with desiccant packs. Some makers go a step further and use vacuum-sealed storage bags to keep filament fresh for months. (👉 Check out our UFM PrintStation Storage designed specifically for safe filament storage.)

Q: Can I mix different brands of filament?

A: Technically, yes—if they’re the same type (e.g., PLA from two brands), they will print. But keep in mind that print settings, color tones, and quality may vary. For consistent results, especially on projects where strength or aesthetics matter, it’s smarter to stick with a single reliable brand.

Q: Do I need a special printer to use flexible filaments like TPU?

A: Flexible filaments can be tricky. On Bowden-style printers, TPU often jams or buckles. For best results, use a direct drive extruder, which feeds filament straight into the hotend with minimal room for bending.

Q: What are the warning signs of bad filament?

A: Watch out for:

-

Popping or sizzling sounds during printing (a sign of absorbed moisture).

-

Inconsistent extrusion, leading to weak or uneven layers.

-

Excessive stringing or blobs.

-

A brittle, snap-prone feel when bending the filament.

If you notice these, it may be time to dry your filament—or upgrade to a higher-quality brand that ensures consistency.

Your Journey to Perfect Prints Starts Now

You now have the inside scoop on how to stop wasting money and start producing flawless 3D prints. The 7 pro tips we’ve covered—ranging from choosing the right filament type to proper storage and understanding your printer’s capabilities—are your roadmap to more consistent results.

By putting this knowledge into action, you’ll save money, avoid frustration, and unlock the true potential of your 3D printer. Remember: every great print starts with an informed choice.

Take Your Printing Setup to the Next Level

A clean print is only part of the story—a clean, organized workspace makes the entire process smoother. Simplify your post-processing and keep your setup efficient with the SwiftBuilder MKII Resin Vacuum, the ultimate tool for makers who want professional-quality results without the mess.